Core Assembly

The transformers are built with fully annealed, Cold Rolled Grain Oriented (CRGO) laminations. Fully mitred designs are used to ensure low losses/low magnetising current & low noise levels.

Core Coil Assembly

It is always ensured that all the HT & LT coils are preshrunk, varnished and dried before assembly. Special care is taken to make the core coil assembly mechanically and electrically strong. For this, vertical and horizontal supports of PC Board of required strength & size, suitably interlocked, are provided. Each HT coil section is separated by press board rings. Yoke insulations are made of PC Board, permalli wood or Bakelite sheets, depending upon the size and voltage class of the transformer. LT leads are taken to the bushing terminals through proper bus bars/flexible jumpers. HT tapping leads & line leads are taken to the respective terminals through SRBP tubes-all suitability braced. Complete assembly is then dried in thermostatically controlled oven at 90 C. At the end of the drying cycle, the core assembly is further tightened to take care of the shrinkage.

Tanking

The tanks are made of mild steel and are of welded type. Suitable stiffeners are provided for robust construction. Enough cooling radiators made from elliptical tubes/pressed steel fins are provided to maintain the temperature rise within specified limits.

Insulation & Oil

All insulating systems are carefully selected with due consideration given to electrical, mechanical & thermal properties of insulation. The oil is used as a coolant and insulating medium. It is tested for di-electric strength as per IS:335, before topping up. Second filtration is carried out just before despatch.

Testing

Each transformer is subjected to all the routine tests as recommended by IS:2026. On specific agreement, transformers can also be subjected to certain type tests/special purpose tests. Purchaser may depute his representative to witness these tests.

After Sales Service

On receiving information about any trouble in the transformer, our team of expert mechanics is promptly deputed, without fuss.

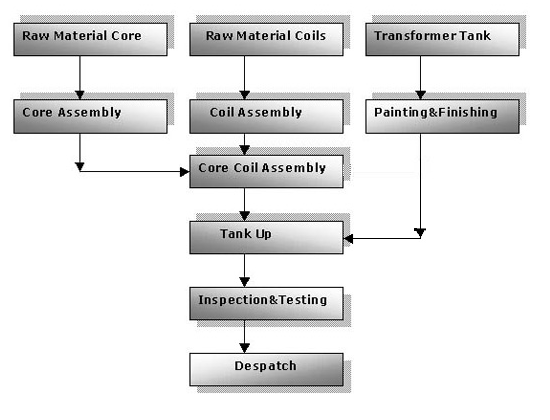

Process chart

[/vc_column_text]